We are pleased to announce the installation of the Ultrasonic Antifouling system on two IHC Easydredge®2700 vessels.

Royal IHC is an innovation leader in the maritime industry. Their mission is to create an industry that is more efficient and sustainable. The ultrasonic antifouling systems installed to protect the box coolers on two IHC Easydredge®2700 vessels contribute to their admirable mission. At LSC, we believe that collaboration is the only way to build a more environmentally friendly maritime industry.

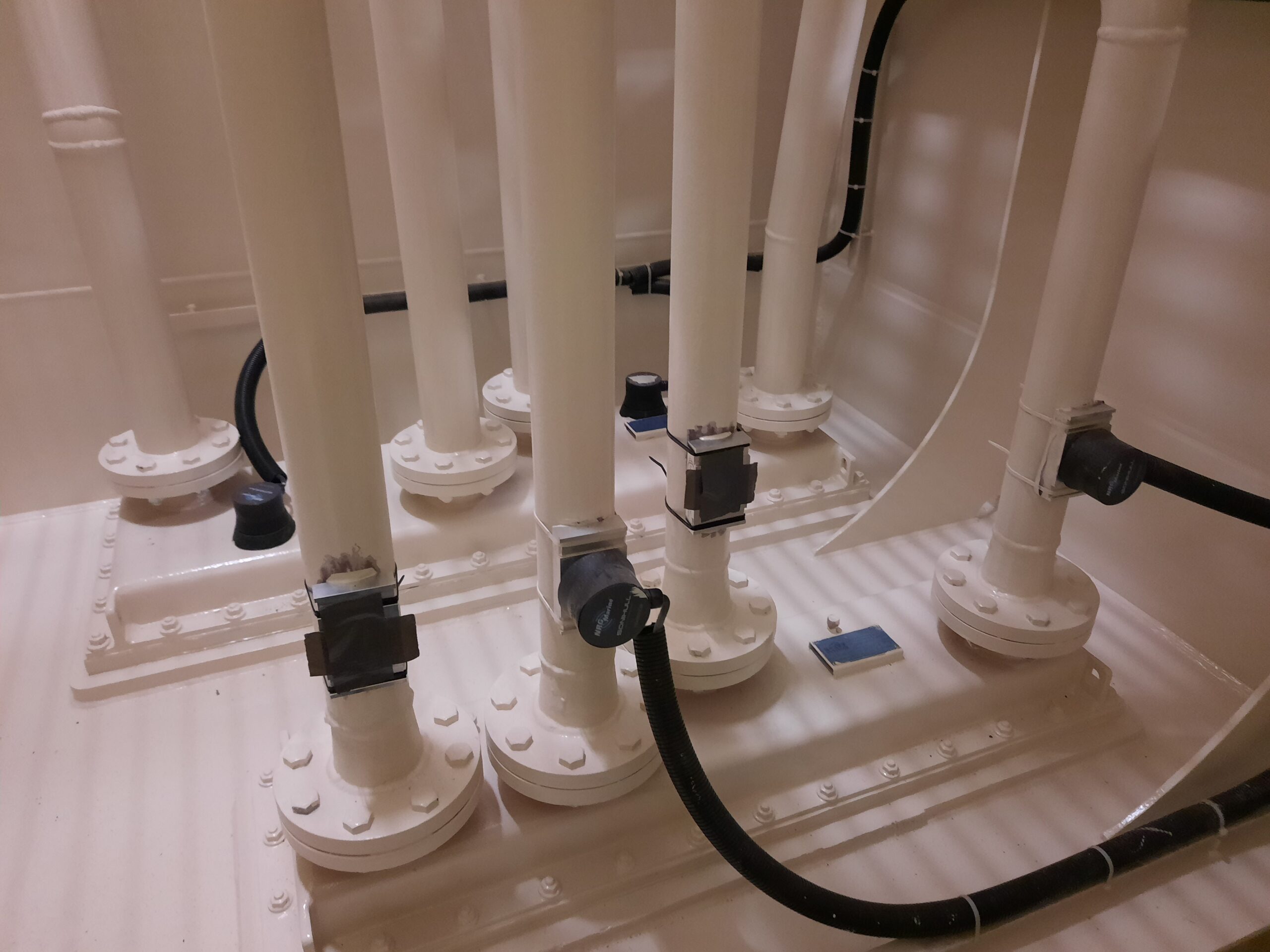

The image above shows four of the six transducers installed to protect these box coolers. The transducers are bonded to the cooler cover. However, some cooling covers do not have enough space for the transducers. To solve this issue, pipe adapters are used to ensure proper transmission of sound waves into the structure. The transverse sound waves carry the metal structure all the way down to the box cooler pipes. Microscopic gas implosions prevent the first layer of fouling from adhering to the surface, without causing damage or metal fatigue to the pipes.

The IMO emission targets aim to drastically reduce the total annual greenhouse gas emissions from international shipping. The emissions of the Ultrasonic Antifouling system are only from the required power of 3.6 Watts per transducer. Replacing copper anodes with the Ultrasonic Antifouling system also reduces downstream supply chain emissions. Eliminating the need to replace copper anodes every two to five years reduces the demand for copper mining and all associated pollution. Additionally, with proper maintenance, the Ultrasonic Antifouling system has a lifespan of 10+ years, making it a sustainable choice.

We are proud to contribute alongside Royal IHC to a more efficient and sustainable maritime industry.